A New Future in Electric Coral Reefs

By Chad Scott

By Chad Scott

Coral reefs around the world are being lost at an alarming rate due to the localized effects of human activities, natural causes, and the global effects of climate change. One of the more unique methods used to restore and preserve corals in the face of oceans that are becoming warmer and more acidic is the use of electric artificial reefs, or Biorocks™. Biorocks™, or mineral accretion devices, were invented by Dr. Wolf Hilbertz, and use a process of sea electrolysis to improve the growing conditions for hard corals and other marine life.

On these electrified structures, corals and other animals grow faster, and can better survive problems such as temperature changes, disease, predation, or ocean acidification. Corals growing on the devices not only are healthier than their natural counterparts, but also have a higher reproductive output – meaning more larvae to seed and restore damaged coral reefs nearby.

Although the technique was patented in 1996, the vital technology is not yet widely used around the world. Although the technology is not very complicated, it is more expensive than many other artificial reefs and requires regular maintenance, but that is not the main reason why you may have never seen or even heard of them. One of the major problems with the technology is that up until recently is has remained patented, trademarked, and proprietary information of the Biorock Company. Because of these ownership and patent restrictions, the technology has not been freely available to the reef managers and local communities who could have benefited most from its use. 19 years has essentially been lost, over which time tools that could have helped save reef areas and preserved coral diversity in places around the globe has been forestalled.

But fortunately that is changing. Many reef managers, coral restorationists, and reef scientists have been waiting for the time when the patent on the mineral accretion technology would expire so they could begin to further develop the technology and independently verify many of the claims made by its creators. Often the year 2015 has been thought to be the year in which the patent would expire, and had many of us waiting. However, according to the United States Patent and Trademark Office website (accessed on 19 August 2015) the patent (No. 5,543,034) actually expired on 1 September 2008 due to “NonPayment of Maintenance Fees Under 37 CFR 1.362”.

With this development, it is very interesting times, as the electric reefs start to become more widespread. However, due to the issues over the last few decades, many reef managers are unsure about the technology, as they still believe that it is too expensive or technically challenging. In fact, the technology is very accessible, and can cost the same or even less than some other widely used artificial reef and restoration techniques. We hope to dispel some of those myths here –

MYTH #1: MINERAL ACCRETION DEVICES ARE TOO EXPENSIVE

This is not so much of a myth, but a factor of previous ownership on the technologies patent. Although installing a Biorock™ is expensive, most of that money goes to the company, and not the project materials.

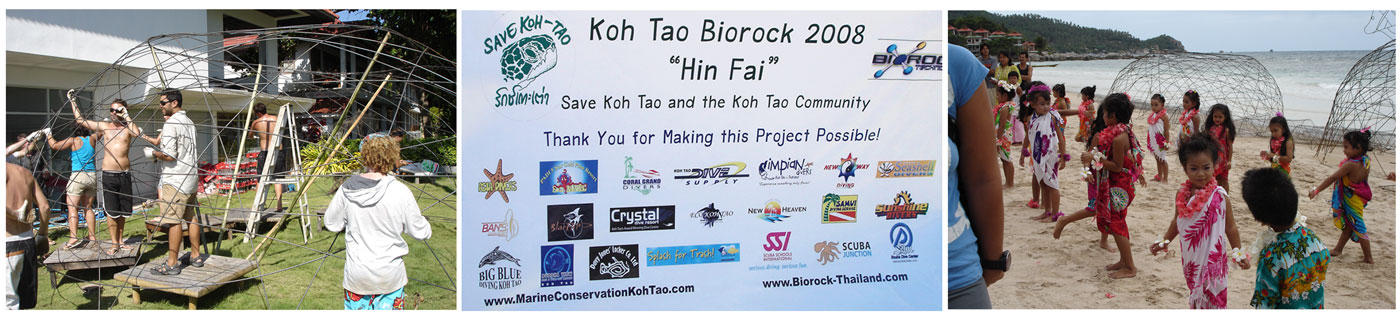

For example, in 2008 the Save Koh Tao Group, was able to rally support from 17 local dive centers and over the course of a few months raised 1 million baht (About $28,000 US) to build a Biorock ™, known as locally as Hin Fai (read more about Hin Fai here). It was the most money the community group ever raised or spent for their yearly projects, with most successive large artificial reef projects costing in the range of 300,000 to 500,000 Thai Baht. When it was built, the Hin Fai site was the largest Biorock™ structure in the Gulf of Thailand, and also the first to use a prototype underwater transformer to improve efficiency and reduce electrical consumption. However, very little of the money spent on the project went back into the local economy, and most of it went to the licensing fee.

As a community group, the owners of the company gave Save Koh Tao a discounted licensing fee of 250,000 Thai Baht ($7,000 US). Which essentially means that we have a Biorock™, however in the end there was never anything tangible given for this single most expensive item in the project – other than a handwritten receipt. If instead of being a community group, a hotel or for-profit business wanted to do the project this fee would have been even higher. The next largest expense was for the anode material, which cost 175,000 Baht. If asked what it was, the company would reply that it is a space aged metal alloy developed by NASA. Which may be true, but a less obscure way to call it is titanium-platinum alloy. Which, interestingly, is not even the most efficient material to use, but was the metal used in the original patent from 1996. By 2008 better anode materials were available, such as the MMO Titanium-Platinum meshing available for $30 dollars a sheet on ebay.

Another large expense was the pilot-project underwater transformer, known as the Biorock™ On Location Power Supply (BOLPS). The unit cost 150,000 Baht ($4,200 US), which included no guarantee or warranty, and the on-site users were not given any training or instructions for inspecting or maintaining the unit, as everything inside was proprietary. Within 2 years it had broken down, and the company quoted $2,000 US to come over and inspect it, from an island 2 hours away.

Including the flights, expenses, and consulting fees for the Biorock™ company, a total of 703,500 Baht ($19,800 US) was paid to the Biorock™ Company for the Hin Fai Project in 2008, with only 221,800 Baht being spent locally [artificial reef (cathode) materials, labor, tools, marketing]. This shows that although the devices have previously been very expensive, they don’t have to be anymore.

Lately we have been experimenting with a new generation of mineral accretion devices that have been designed by one of our ex-students. The new units are solar powered, and have a floating anode and transformer unit. Not only is the technology smaller and much more advanced, it also features a viewing window so you can easily read the voltage and amperage being produced, and a warning indicator light for leaks or problems. In a few months he was able to create a much better and cheaper unit than the BOLPS, which was essentially a cheap battery charge in a massive steel container. Each of these experimental solar units costs around $500 US, and will power a small artificial reef or can be combined with additional units to power larger structures. He has set up a facebook page to help others learn about what he has come up with.

Of course as more people around the globe start to develop and advance this technology it will only get cheaper and more available to the local communities and reef managers who need it.

MYTH #2: MINERAL ACCRETION DEVICES ARE TOO TECHNICALLY CHALLENGING

While the devices are much more complicated than a steel or concrete artificial reef, you do not need a degree in electrical engineering to build one. Essentially the process is what is known as electrolysis. Electrolysis is a process by which electricity is passed through water, and has many applications in everyday life such as plating metals, preserving piers or boats, removing rust, and even removing unwanted hairs. A DC current flows from one metal, known as the Anode, through the water to another metal, known as a Cathode. Together the two metals are known as the electrodes. Different processes occur at each electrode, with the water around the anode becoming acidic and around the cathode more alkaline. Different ions, or elements, in the water will be attracted to either anode depending on their charge. After the alkalinity increases beyond a pH of about 9 at the cathode, then minerals start to attract and accrete there.

So essentially what is needed is a power source, two metals for electrodes, cables, and a transformer. The power source will vary depending on many factors such as location, budget, and availability. The corals grow on the cathode, which is the artificial reef structure usually made from steel rebar, and is cheap and readily available around the world. It is already widely used to build artificial reefs, meaning that many existing structures can readily be fitted with the devices. The other electrode, than anode, must be a more specialized metal, and is usually a titanium-platinum alloy. Although more expensive than steel, much less of the anode material than cathode is used, and generally one 30 cm x 30 cm sheet will suffice for a small (1-2 m diameter) artificial reef. The cables are standard, and the transformers don’t need to be much more complicated than the one that charges your smart phone; which can easily be purchased online depending on the power source you are using. Generally the structures run at about 8-10 volts, with a current density of about 0.2-0.8 amps/m2 of cathode metal area.

That might not be enough info to get you running out to build one, but with that overview and a few hours more on google you will know everything you need to in order to build one. The point is that it will take a little bit of time to learn how to build it, but for the first time ever there are going to be people out there who will actually teach it to you. Rather than having to purchase some black box product from an overseas company, users will be able to use the parts and resources available in their home countries and modify the basic design to fit their needs and budget.

So what does the future hold for this technology? Already it has many applications, including building artificial reefs, creating coral nurseries, solidifying marine sediments or rubble fields, creating breakwaters and slowing beach erosion, and more. In the future, using solar or wave powered units, the technology will be ‘untethered’ from the land and can be applied to a much wider variety of areas and applications.

We foresee that by creating permanent mid-water coral nurseries with the technology and farming a diverse range of corals on them, it may be possible to create ‘seed’ sources; large fecund adult colonies to reproduce and provide larvae to replenish stressed reefs. In the same way, large suspended units could be used to create “stepping stones” between coral reef areas, thus increasing reef connectivity and reducing the isolation of some reef areas to larvae flow or emigration of species. Floating reefs could be made well away from land and the direct effects of human activities, these reefs could essentially serve as banks of biodiversity in the same way that some people collect and store heirloom seeds for plants.

Another potential use for the technology would be to turn off shore oil platforms into artificial reefs by electrifying the entire structure as a cathode. While in operation the mineral accretion would build and become host to a wide range of marine life. After the platform is decommissioned and the electricity turned off, it could be left on its own, forming an off-shore artificial reef or artificial coral atoll.

The technology can furthermore be integrated into all types of marine aquaculture projects, such as those for sea cucumbers, sea urchins, bi-valves, and more; increasing yield to provide more food and money to local communities dependent upon the seas resources.

There is limitless potential for refining the sea water electrolysis technique and applying the technology in new ways. As the technology enters the creative commons and becomes more available to those who need it, innovations and creativity will bring about the realization of new benefits that previously have been stifled by patents and legal ownership. The future of this amazing technology is here, and it is up to all of us to decide where we want to take it.

The mineral accretion technology is not something that is going to bring back the worlds dying reefs or solve the impacts of climate change. However it is one of the tools that local reef mangers have to address this crisis, increase reef resilience, and preserve species for the future. Combined with all the other tools available into a holistic management system, reef managers will stand a better chance of ensuring that corals reef continue to be one of the planet’s most amazing and important ecosystems well into the future.